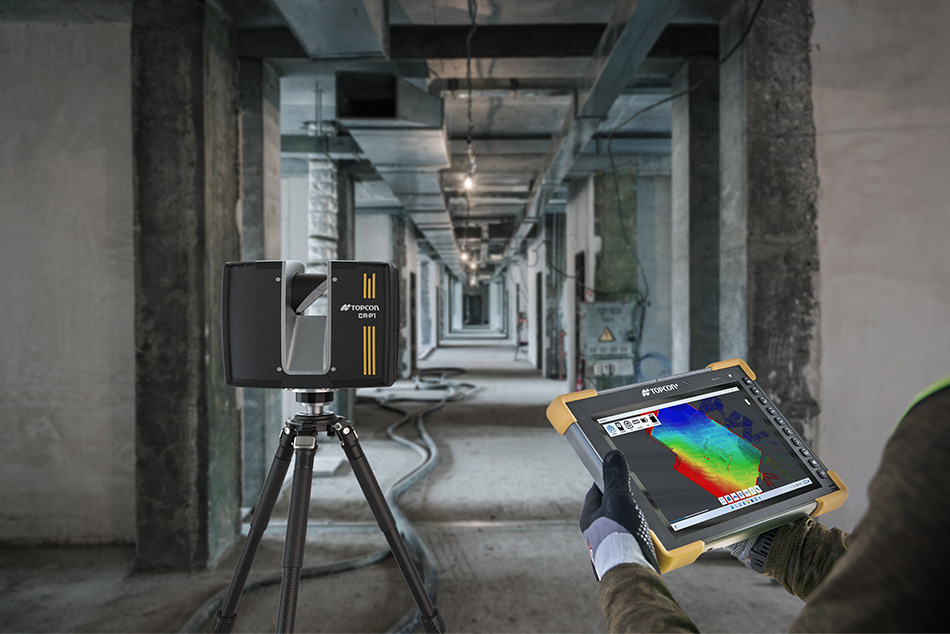

Topcon’s GT-Series, LN-Series, GTL-Series and MS-Series total stations feature powerful electronic distance measuring devices (EDMs), strong battery lives, advanced prism tracking, Bluetooth and Wi-Fi communication modes, and ample memory. They are also designed for rugged use and water resistance.

Choosing the right equipment for your application involves considerations such as range, accuracy requirements, Hybrid Positioning capabilities, and other factors. The following chart outlines key specification differences in Topcon’s robotic total station lineup.